Break Neck (Case Study)

Case studies

HL Technology recently completed the remarkable feat of transforming a customer's idea into a functional medical device ready for market deployment, in just six months.

This success was made possible by close collaboration between our team and the customer, combined with our expertise in product development and project management.

It all started when the customer came to us with a clear vision for a new medical device that would revolutionize a specific area of medicine. After extensive initial discussions to understand the customer's requirements, our team of engineers and designers began work on turning this idea into reality.

The development process was rigorous and well planned. We started with the design phase, creating virtual models of the instrument to obtain validation from the customer. Once the design was approved, we moved on to the prototyping phase, where we built working prototypes for in-depth testing to ensure the safety and efficiency of the instrument.

In parallel with the development, our team produced and implemented all the necessary quality documents in accordance with the standards and regulations in force in the medical industry. This included design documentation, validation plans, manufacturing procedures, quality testing and many other essential elements to ensure regulatory compliance and product safety.

Once the prototypes had been validated and all the quality documents approved, we launched the production phase. Thanks to our know-how, we mastered the production process while maintaining high standards of quality and reliability. In just a few months, we managed to produce the first series to the customer's specifications.

As a result, we delivered the first series of the medical instrument to the customer within the agreed timeframe. This delivery marks not only the achievement of the customer's initial objective, but also the realization of an innovative instrument, where our technology will contribute to improving healthcare and saving lives.

In summary, thanks to close collaboration, solid technical expertise and efficient project management, HL Technology has succeeded in transforming a simple idea into a revolutionary medical instrument in just six months, while meeting all quality and regulatory compliance requirements and being absolutely faithful to our customer's wishes and needs.

The best of HL Technology know-how

-

Safety

Instrument factory calibrated to the torque specified by our customer for maximum safety.

-

Ergonomics

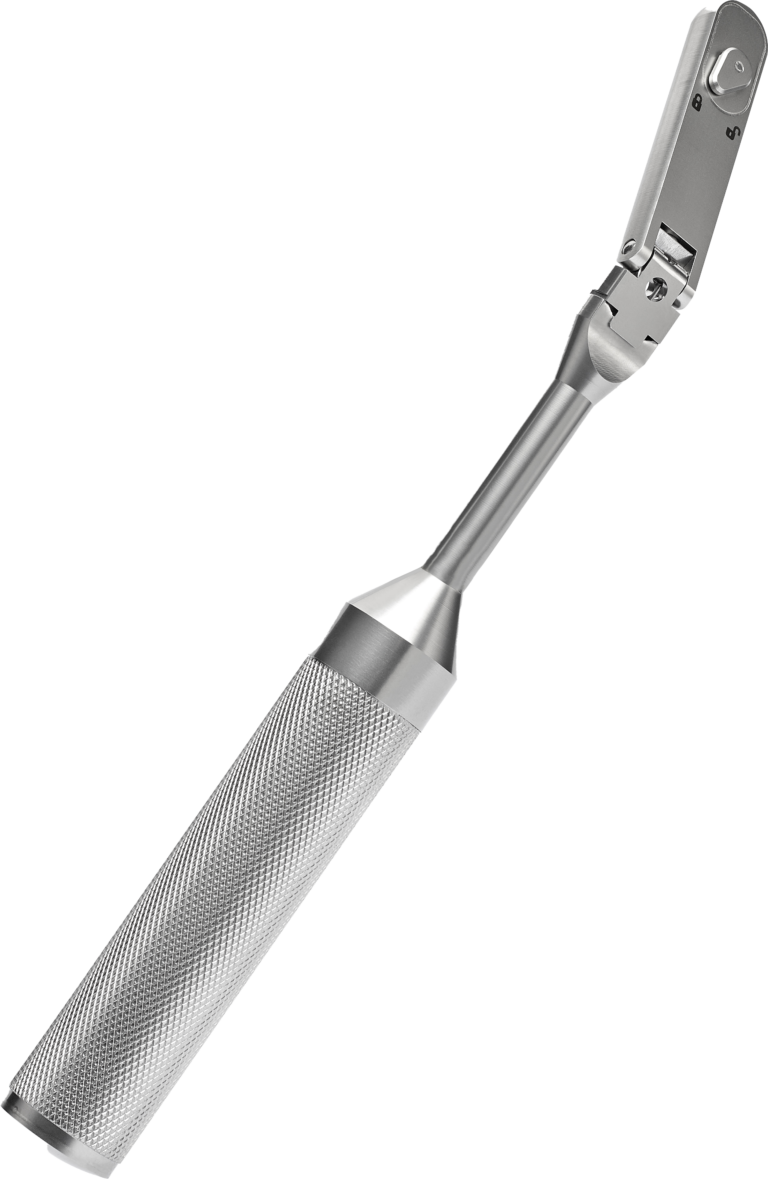

Break neck mechanism developed to reach the thoracic cavity while maintaining an ideal grip and tightening in a minimally invasive way.

-

Design

Torque mechanism incorporating all of Hl Technology's expertise, including the ratchet function, in a 100% new angular instrument with adjustable angulation.

-

Compatibility

Interface customized to our customer's specifications

-

High precision

High precision and torque stability over the entire lifetime.

-

Quality

As an ISO 13485:2016 certified company, we developed and supplied all the quality documents inherent in this project so that our customer could obtain and market the product in the USA, including FDA certification.

Perfect ergonomics

The reduced size of its head and its articulation mean it can be used minimally invasively, and its ideal ergonomics simplify the surgeon's work.

Customization options

Your needs are our challenges. Give us your idea, and we'll realize it from development to marketing.

What's more, your logo will be engraved and the intermediate or final packaging will be produced to your specifications.

Find out more about these services

We will be pleased to make you a tailor-made proposal and answer any questions you may have.